SOUR SERVICE GRADES

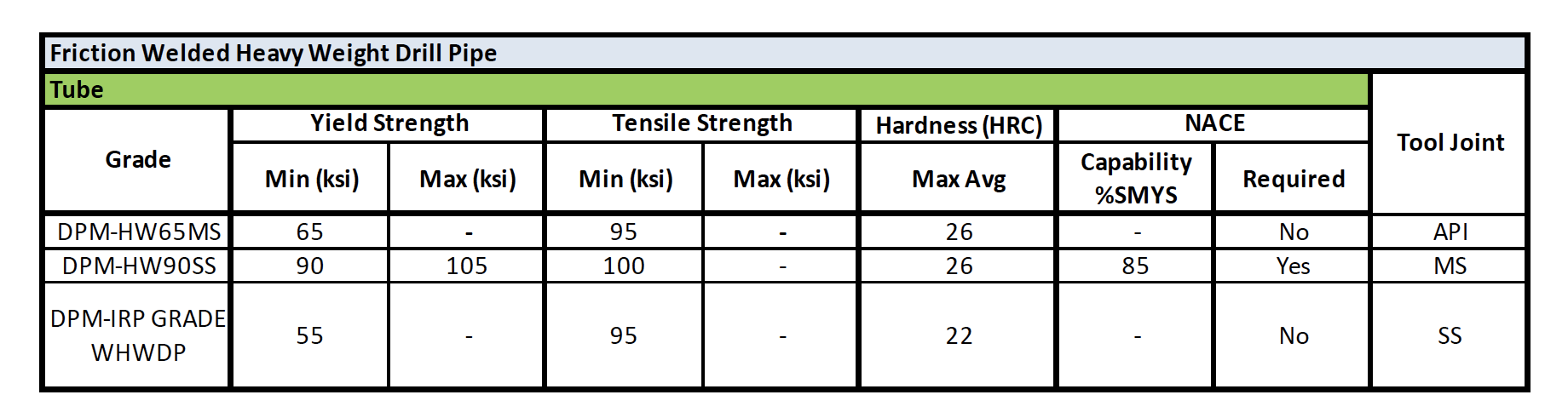

DP-Master proprietary sour service grades for heavy weight drill pipe offers improved resistance to sulfide stress cracking. The material has controlled yield and restricted hardness.

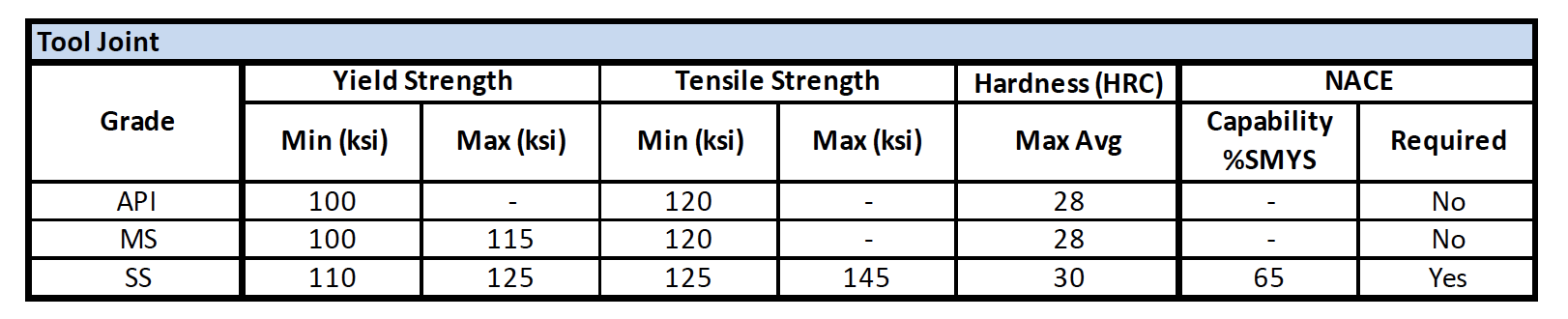

- DPM-HW65MS is suitable for use in mild H2S environment with 65,000 PSI SMYS tube and industry-accepted API tool joint with specified minimum yield strength 100 KSI.

- DPM-HW90SS has a controlled yield strength tube (90 to 105 KSI) with restricted hardness. The tube undergoes NACE ™-0177 Method A test at 85% of the specified minimum yield strength and offers optimum resistance to fatigue cracking and crack propagation. The tool joint has a controlled yield (100 to 115 KSI) with restricted hardness.

- IRP GRADE WHWDP is designed based on IRP 1.8 specifications and has a minimum yield strength of 55 KSI and restricted hardness for the tube. The tool joint undergoes NACE ™-0177 Method A test at 65% of the specified minimum yield strength thus providing greater resistance to sulphide stress cracking.

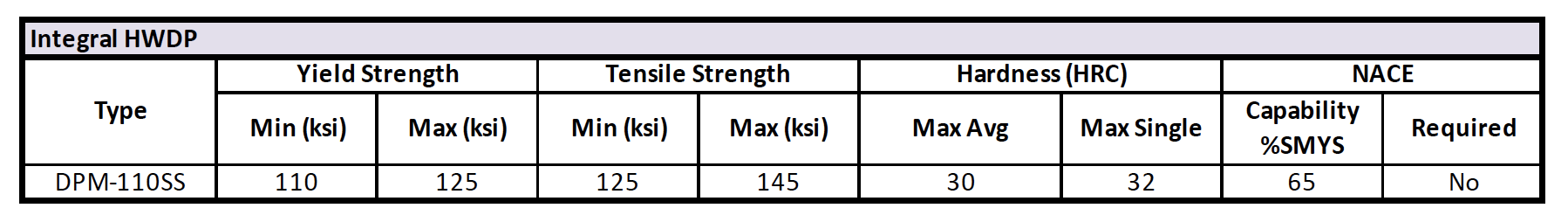

- DPM-110SS grade material is used for integral heavy weight drill pipe solutions. Manufactured using a forged solid bar, DPM-110SS is able to withstand NACE ™-0177 Method A test at 65% SMYS.

- Customised grades are also available based on customer’s requirements or specifications.

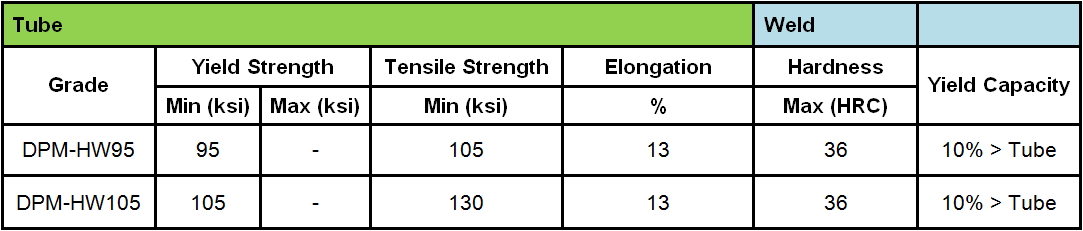

HIGH STRENGTH GRADES

DPM-HW95 and DPM-HW105 high strength welded HWDP with 95,000 PSI and 105,000 PSI SMYS tubes and 120 KSI tool joints and integral HWDP are suitable for higher strength usage requirements.