May 19, 2021

DPM-EduSeries Topic 9: Cold Rolling and Make & Break

Welcome to another post in our DPM-EduSeries! Today we will be looking at Cold Rolling and Make & Break!

Cold Rolling and Make & Break are optional processes for API connections but mandatory processes for DPM proprietary connections.

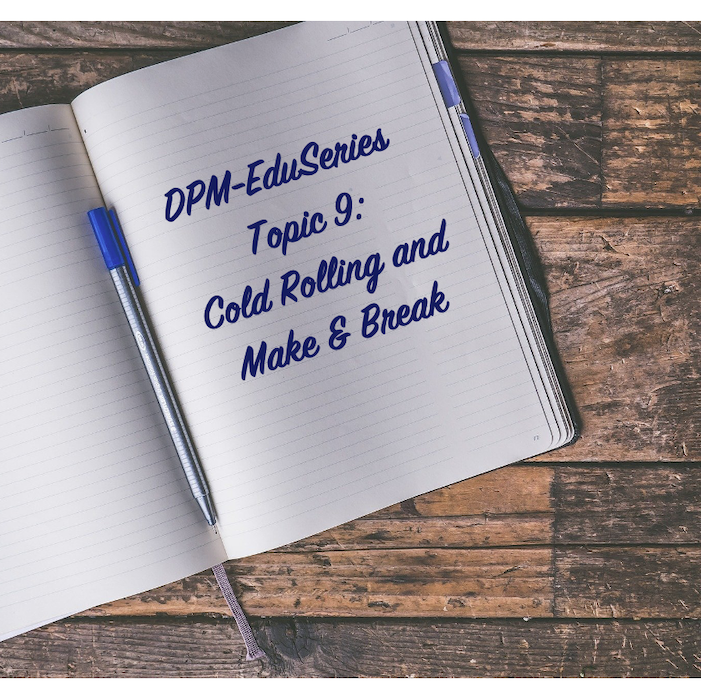

The purpose of cold rolling the thread roots and flanks is to induce a compressive layer which reduces the susceptibility to cracking thus enhancing fatigue resistance. A macroscopic image of a cold rolled thread root is shown below.

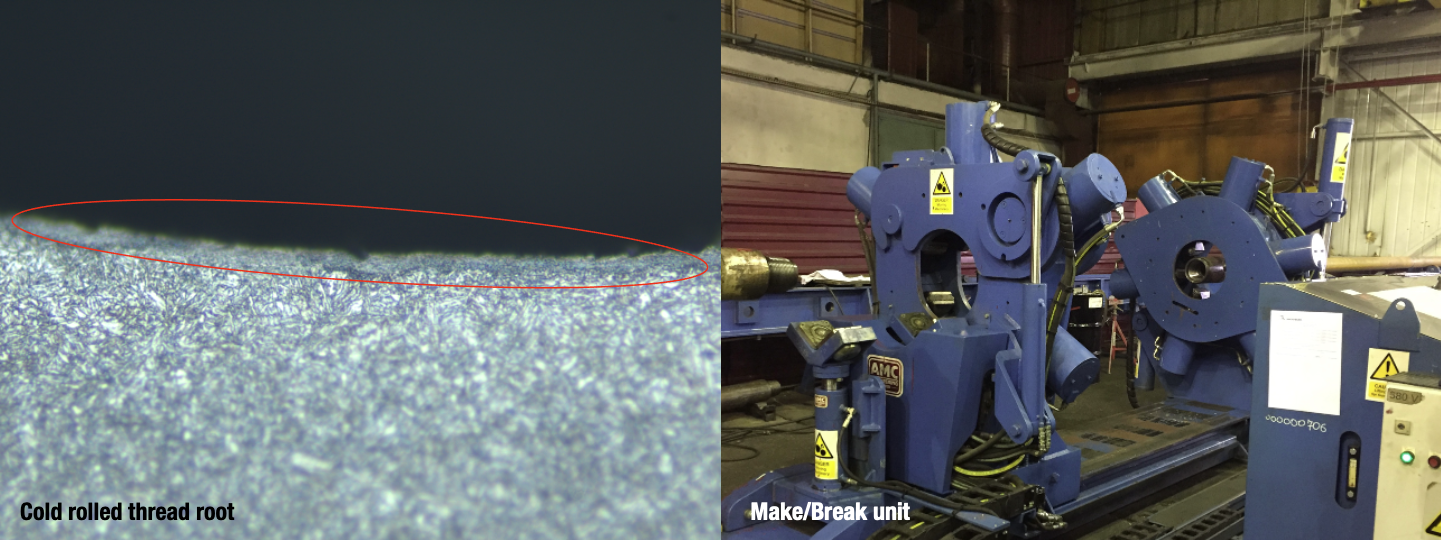

Make & Break of new tool joints reduces the likelihood of service damage to the connection including galling and downhole make-up. It is recommended to carry out the Make & Break process at the tool joint manufacturing facility in a controlled environment instead of on the rig to eliminate rig handling time and cost. An example of a make/break unit is shown below.

#DPMaster #DrillPipe #DrillString #DPMEduSeries #Manufacturing #DPM